Bangladeshi scientist invents biodegradable carry bag to replace plastic

Scientist Mubarak Khan says he needs help for commercial production and popularizing his jute cellulose bags to replace polythene

By SM Najmus Sakib

DHAKA, Bangladesh (AA) – A Bangladeshi scientist who has invented a low-cost biodegradable carry bag seeks investments to manufacture and popularize the bag to replace polythene in daily use and the packaging industry.

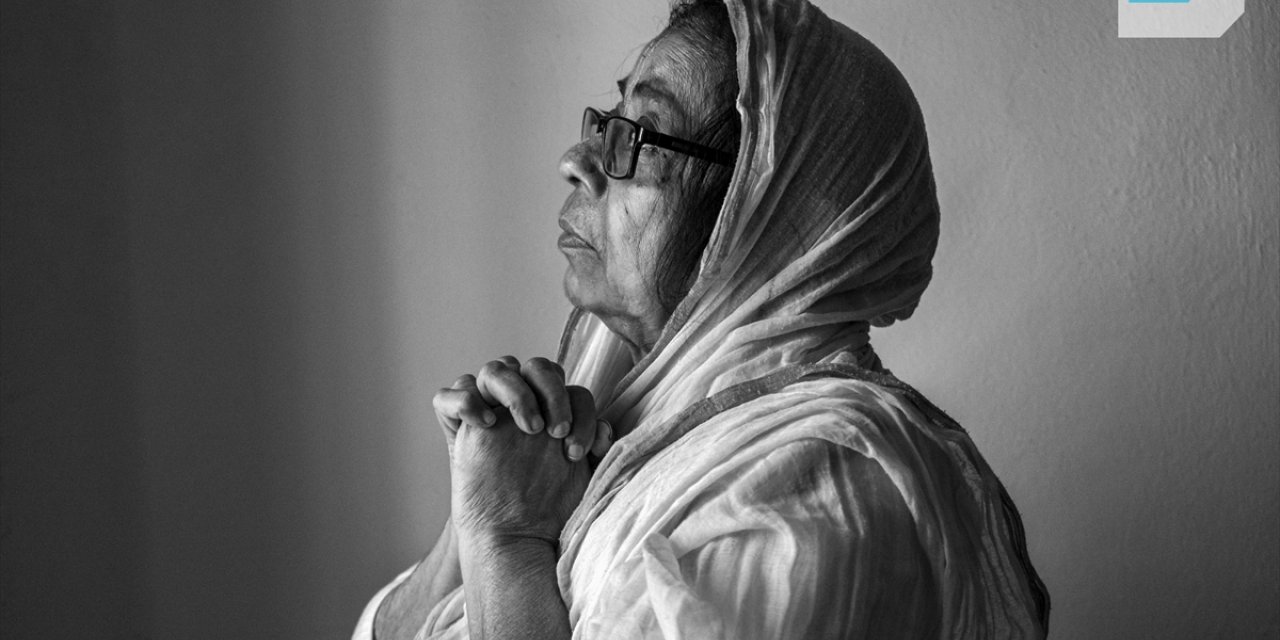

Speaking to Anadolu Agency marking the World Paper Bag Day on Tuesday, Mubarak Ahmad Khan, chief scientific adviser at Bangladesh Jute Mills Corporation, claimed that his biodegradable carry bag made of cellulose sheets popularly known as Sonali bags has the potential to transform the world.

Khan, who was formally associated with the Bangladesh Atomic Energy Commission said he had invented the biodegradable and eco-friendly bag from jute cellulose and polymer in 2017. It can be used in garment packaging and for food packaging for commodities such as rice and sugar and even for dairy milk.

“We have developed a machine which can produce 60 jute poly bags in a minute. However, we need more advanced machines to go for commercial production and to meet local demand to replace polythene bags in the local market,” he said.

The scientist said that further research and commercial production needs 5 billion takas ($53.1 million). He said while the government has agreed in principle, it has confirmed yet.

“So far, I have received 200 million Taka ($2.1 million) as a grant in two separate allocations from the government since the project got started. Of the total, I only could withdraw a single instalment out of the two allocations due to a technical delay in the government system,” he added.

Khan said Bangladesh like many other countries have banned the use of polyethene. But the country is producing tons of polythene bags and plastic waste every year.

“A good number of foreign parties want to sign deals to get 20-30 tons of jute bags per day, but I couldn’t shift to commercial supply as I am still in the development stage of the machine. We need bigger machines to this effect,” he said.

He said that he was negotiating with a Turkish company, which had offered to design and develop a bigger machine for commercial production.

- Bangladesh leader in jute production

“Our jute bags now cost 10-15 Taka (11-16 cents). If we can avail of major funding, then the retail price could be reduced to less than 1 cents. Bangladesh can hold and lead a global market in the bioplastic bag,” he said.

He also urged city dwellers living in high-rise buildings to start planting jute on rooftops to popularize it.

Md. Abdur Rauf, secretary to the Ministry of Textiles and Jute, told Anadolu Agency that there were some challenges the commercial production including developing the capacity of the machine.

“Once we meet all we need in the mass production process, there will be no funding inadequacy. Meanwhile, the project will attract private investment and entrepreneurs for commercial production,” he said.

He said for the large-scale production of bags, there is a need to switch to mechanized sewing as it is still being done by hand.

“We have already developed some small sewing machines, but we need a bigger one,” he added.

According to experts, the jute polymer is produced by extracting cellulose from jute fiber and is entirely biodegradable and recyclable.

The eco-friendly material decomposes within three to four months after being buried in the soil.

Jute is a major fiber crop grown throughout the world that is recognized as the second most important vegetable fiber after cotton in terms of global consumption and production.

Bangladesh had 300 polybag factories in 1999, which jumped to between 700 and 1,000 by 2021, with units spread across rural areas, according to the Environment and Social Development Organization (ESDO).

Kaynak:![]()

This news has been read 132 times in total

Türkçe karakter kullanılmayan ve büyük harflerle yazılmış yorumlar onaylanmamaktadır.